Things to Consider When Purchasing a Flow Wrapper | On the Pulse of Packaging Episode 20

💡 This episode is packed with actionable advice to help you make a confident, informed decision on a flow wrapper

In this episode of ‘On the Pulse of Packaging’, we sit down with Tony to dive deep into the key factors you should consider before purchasing a flow wrapper. Whether you’re upgrading your packaging process or making your first investment in automation, Tony walks us through critical questions and insights that are often overlooked.

WE DISCUSS:

- Choosing between branded or non-branded (registered print) film and how that impacts cost.

- The importance of understanding how many product sizes you’ll need to accommodate.

- Why support: training, parts availability, and technical support are essential—especially if it’s your 1st flow wrapper.

- What the acquisition process looks like, including Factory Acceptance Testing (FAT) and PAC’s customized setup pages in the machine manual.

Tony also highlights the long-term benefits of working with PAC Machinery or one of our trusted packaging distributors.

SHORTS – SHORT CLIPS FROM THIS EPISODE

Tony is Talking Flow Wrapping 101 – and what’s great about this method of packaging

Talking film! Branded (registered print) film & non-branded film for Flow Wrapping

Consider product size when purchasing a flow wrapper.

Thinking about buying a flow wrapper? Don’t make this rookie mistake—ignoring support.

Transcript:

Hi everyone and welcome back today we’re unpacking what you really need to know before investing in a flow wrappers. Whether you’re just starting out or upgrading your packaging setup there are some key factors you might not have considered. Joining me is Tony from PAC Machinery who’s really knowledgeable about flow wrappers and he’s here to share practical tips that can save you time and money. Let’s jump in. Hi Tony!

Hi Shannon how are you? Great How are you? I’m doing well thank you!

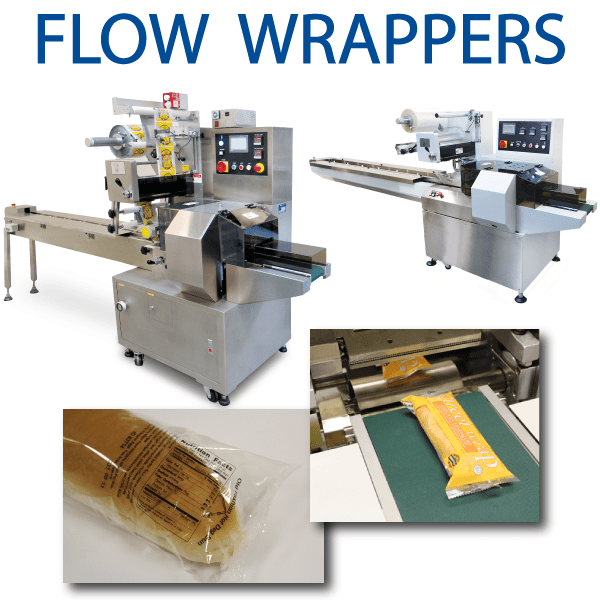

So yeah I wanted to uh talk about a few considerations to make when when looking at purchasing a flow wrapper and for those of you that aren’t familiar with flow wrapping you’ve probably seen seen a flow wrap product like hundreds of them thousands of them in the if you walk into any grocery store right it’s got a it’s got a thin seal on the bottom it’s got the saw to seals here makes it easy to to tear open uh it’s it’s probably one of the most popular ways of packaging a product especially food and there’s several reasons for that one is because it’s one of the most aesthetically pleasing packages right for products in retail and part of that is because you can get a very nice tight fit with that package around the product.

The second reason is that it’s if not the least expensive it’s close to being the least expensive way of packaging per product when it comes to material costs and then the third is it’s highly productive you can do thousands to 10,000s depending on your on your flow wrapper per hour so it’s a very efficient way of packaging products tony one of the first decisions people face is whether to use branded or non-branded film also known as

registered print film what should companies keep in mind when choosing

between those options so a flow wrapper uses a roll of film that basically comes down on top of a former and that product flows into that former while the film is wrapped around the product and then sealed as it comes out of the machine that film right you have to look at whether you’re going to be doing branded film or non-branded film so in this case right you have a branded film you’ve got the product picture you’ve got the nutrition information you’ve got all that stuff on this package sometimes you don’t need that sometimes people just need like clear film because they’re going to maybe put it in a master pack or a box that’s going to have all that information on there but that’s a very important consideration to make because not all machines can do registered print film so if that’s something you need or you plan on doing in the future you have to make sure that the machine you’re going to get can do registered print fill and for those producing multiple versions of a product how can they manage film costs

is there a smart way to design for flexibility so if you’ve got multiple flavors let’s say I got 5 6 7 8 you know 10 flavors if you’re just starting out and this is your first flow wrapper that could get very costly very quickly because you’ve got to buy minimum quantities of custom printed film from your film provider and so if you’ve got to do that for five to 10 different flavors the initial cost could be prohibitive so that’s something else to consider a lot of times what people will do is they’ll maybe get a static design for one you know maybe their logo all that kind of stuff and then a lot of these flow rappers will have options of printers so they can print the variable

information like maybe the flavor or the nutrition information for that

particular flavor so that way they only have to order one roll of film to start

off with and then they can do the different the different flavors or whatever it is using the printer right which is going to be much more cost effective to begin with and then once they build their volumes up now they can start ordering custom film for each of the different flavors so those are things to consider on the film side.

Now let’s talk size how does the variety of product sizes affect the type

of flow wrapper someone should buy?

When you look at entry-level flow wrappers they’re good for doing one

maybe two different products but there’s a lot of manual setup to switch between products so they’re not really designed to do a whole variety of of different sizes of products so that’s something else to consider as you go up the food chain and you get into the higher levels of flow wrappers they they come with more options that allow you to easily uh switch between different sizes right so it’s more digital if you don’t have as much manual adjustment to make um but even that at that point you also have to consider that if I’m going to do a very small product to a very large

product there’s only so much that you can do as far as variance in size even with a higher end flow wrapper where you may have to have a second machine if you’re going if you’re going from a really small product to really big product it’s too much of a gap in size so in that instance you either have to get a second machine or you have to get what’s called a second chain for the pitch right so that’s that’s something else to consider so the different

sizes of products are very important support is often overlooked especially

by first-time buyers tony what kind of training and assistance should someone expect when buying their first flow wrapper that’s probably as critical as the price you get or where you get that machinery from uh I see a lot of people go on Alibaba and that kind of stuff and they order machines and then they get delivered they don’t know how to use them if you’ve never uh had a flow rapper before if this is your first time with a flow rapper you have got to have on-site training or you it’ll be a nightmare for you it’s very very important so that that’s something to consider and then the other thing is parts are you going to be able to get parts if some if you need a part for that machine are they available here in the United States or are you going to have to go you know abroad or you even going to be able to get parts right so that’s important and then what kind of technical support right do you get you know so with pack machinery for instance when you order a flow wrapper from us you have uh phone support phone technical support for as long as you own that product and those and that is that’s at no charge to the customer and then the third consideration under support is more to do with your own organization you want to make sure you

designate a lead operator that’s going to maintain and run that machine that knows how to do that at all times right so you need somebody that’s going to take ownership of that process that’s very important as well it’s not flow wrappers are not um are not something where you can just pull somebody off the street that’s never used one and say

“Hey jump on here and start blowing.” It’s not how it works so.

PAC Machinery has something called an FAT which is a factory acceptance test can you explain why having that matters?

Basically a full production run with your film and your product on our

machine either in person at our factory or via a live feed to ensure that the

flow wrapper and the and the film that you have and the product all run the way we say it’s going to run and then one of the other things that we do here at PAC Machinery is when we create your machine we also create a page in your manual specifically for your product with those specifications on that product itself how to set the film up for that product how to set the the product up and all that kind of stuff all the settings and that is an actual

page customized for you in the manual.

Thanks so much for sharing all your insight today Tony that was packed with value.

Hopefully these little tidbits will make it a little easier in the journey of purchasing your next flow wrapper thanks again for all the fantastic tips and

behind the scenes knowledge for more on Flow Wrappers and PAC Machinery’s full lineup head over to packmachinery.com. Thanks for watching we’ll see you next time.