Packaging Story

Rollbag® Auto Baggers > Fulfillment Automatic Baggers > Fun, fantasy, and fulfillment – of the mail order kind

Fun, fantasy, and fulfillment – of the mail order kind

Online shopping and mail order fulfillment is growing at an incredible pace – especially in the apparel sector. Giants like Amazon are responsible for much of the gains, however countless other direct-to-consumer retailers are gaining traction.

The mechanism for e-commerce appears simple to the purchaser. The buyer merely chooses from a seemingly infinite inventory of products (which are available 24/7), enters a credit card number and some shipping information, and products arrive at the door – often the next day. However, behind the scenes, modern mail order fulfillment may require a complex and interdependent set of processes that can involve operations like warehousing and inventory management, order fulfillment, packaging, communicating with customers and shipping merchandise of every size and type in a timely, efficient manner. Since these procedures and business-critical processes can be hard to synchronize perfectly, it’s pretty easy to understand why many businesses outsource fulfillment: the process consumes lots of valuable time and resources. And for those who choose to handle order fulfillment in-house, there is a constant desire to find ways to optimize their labor force or otherwise cut cost.

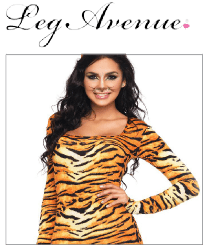

Packaging a fantasy can be a challenge Los Angeles, CA-based Leg Avenue is a successful direct-to-consumer e-commerce company that specializes in lingerie, hosiery and fantasy costumes. Their fanciful merchandise was selling briskly, but the company was having difficulty optimizing its packaging operation. The packaging department was using conventional lip-and-tape poly mailers, but this method required hand packaging and this approach was slowing down production significantly. Leg Avenue was having difficulty surpassing a 80 package-per hour (per worker) threshold. It was obvious that growth would be limited by inefficient packaging, but new problems arose as the company tried a series of different packaging methods. As the company grew, the result of inefficient packaging was showing up on the bottom line. It was the overall method of packaging that had to change.

Believing that the right solution was yet to be discovered, company executives traveled to Anaheim, California to attend the WestPack packaging expo and conference. WestPack is where professionals find the technologies, education, and connections to stay ahead in the global packaging community. In addition to more than 1,900 cutting-edge suppliers showcasing the latest solutions in labeling, automation, package design, and more, WestPack is where professionals seek answers to their most pressing packaging challenges.

Before attending WestPack, the folks from Leg Avenue had learned about a semi-automatic, vertical bagger that utilized pre-opened bags on a roll. While this approach brought them closer to the result they sought, the search continued.

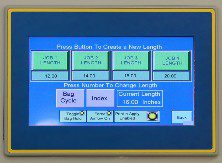

Reaching the PAC Machinery exhibit, the costumers from LA learned that there was more than one way to skin a cat – or wrap a kitty cat outfit. There, Greg Berguig, VP of Sales and Marketing, discussed the Rollbag Magnum Horizontal Fulfillment Bagger. Owing to its unique design, the Magnum delivers a number of major benefits. Unlike baggers that are designed for bags on a roll only, the Magnum can run both bags and poly tubing (which the bagger converts into bags of virtually any length). This feature eliminates the wasteful practice of using one common size of bag no matter the size of the product. This innovation enables the operator to “right size” the bag to the exact dimension required to avoid higher dimensional freight costs incurred by an unnecessarily large bag. There were other advantages for Leg Avenue as well. Since the packaging staff was already familiar with handling products horizontally (they were doing so when hand packaging), loading the Magnum Horizontal required little change in routine. Add to this, the Magnum Horizontal Bagger would integrate better with the existing conveyor system and would require less production-area floor space.

It was clear that tangible economic benefits could be realized almost immediately. Leg Avenue would save money on freight as the bags could be sized properly, and they would save on material costs, as poly tubing would be less expensive than bags on a roll. Adding to its appeal was the fact that the Magnum Horizontal Bagger uses no proprietary parts (should anything ever need replacement) and utilizes standard print drivers allowing connection with almost any automated printing system. There was one additional compelling consideration: Leg Avenue could purchase the machine through a packaging distributor with whom they already worked, and the distributor could provide expert technical support should any be required.

It was a no-brainer. The Rollbag Magnum Horizontal Fulfillment Bagger was the perfect fit for Leg Avenue. In addition to materials and freight savings, packaging production rates were improved by nearly 300% – plus the horizontal orientation (compared to the vertical machine they were considering) provided improved ergonomics for the operators. The search for the elusive packaging solution ended at PAC Machinery.

The PAC Machinery solution After WestPack, PAC Machinery National Sales Manager, Matt Cmeyla, met with Leg Avenue to fine tune the solution. Cmeyla – a proven veteran of the packaging industry – required little time to envision an end-to-end solution based on the Magnum Horizontal Mail Fulfillment automatic bagger that was discovered at the expo. “We had a unique machine-and-bag system that incorporated label application directly on the bags. Plus the Magnum has the ability to change bag sizes on the fly” remarked Cmeyla. The versatile PAC Machinery Magnum Horizontal mail fulfillment automatic bagger with label printer applicator facilitates pre-printing of shipping information, thus eliminating an additional time-consuming step in the packaging process.

Materials were part of the solution

The PAC Machinery coex poly mailer material used in this process served as a complete wrapper and shipper in one. Perfect for packaging intimate apparel, the material is a co-extruded, multilayer film that provides excellent opacity to protect the contents from sight, resists tearing, offers excellent puncture resistance, and is suitable for printing all the necessary shipping information directly on the bag. Hand labeling was entirely eliminated.

Saving space and saving time

Owing to the increased efficiency of the Magnum Horizontal Fulfillment Bagger, Leg Avenue would require fewer workstations while achieving higher productivity at each station. Ease of operation and fast changeover time contribute in large measure to improved efficiency. The PAC Machinery workstation is no larger than a hand-load station, so it makes better use of precious floor space – especially since the bag comes out horizontally on the conveyor, label side up. Overall, the user-friendly Magnum Horizontal Fulfillment Bagger provided Leg Avenue with greater reliability, improved ease of operation, and the ability to quickly change bag sizes on the fly. These attributes led to improved up time, significant labor savings, and the ability to print address, bar codes, etc., directly on the bag. At the same time Leg Avenue was saving on material costs as well. It was a win, win.

The final analysis

Packaging productivity at Leg Avenue increased dramatically – from <80 bags/hour with lip-and-tape bags to the current 300/hour with the Magnum automatic bagger. Unlike training on other systems, which could take up to three to four weeks, training on the Magnum mail fulfillment system was achieved in matter of days – and with the reduced training time, labor costs were reduced measurably. Leg Avenue enjoyed an increase in production that required fewer station managers and a streamlined packaging process that greatly reduced the need for hand packaging. Overall, Leg Avenue achieves better, faster results at about two-thirds the cost of other systems.

"We explained that the unique Magnum Fulfillment Bagger would deliver real savings in a couple of ways: They could reduce labor expense, and at the same time reduce material costs as well.”

Greg Berguig, VP Sales and Marketing Tweet