Packaging Story

Covid-19: Responsiveness counts now more than ever before

Covid-19: Responsiveness counts now more than ever before

With the rapid and devastating onset of Covid-19, many of the companies in the United States who supply essential medical devices and supplies were caught by surprise. True, it was a confusing time – with facts, opin- ions and next-steps wrapped in a swirl of uncertainty. Some companies, however, were able to steer clear of the confusion and take thoughtful and decisive steps toward a solution – even if the solution was simply gearing up for massively increased production. Midland, GA-based Path-Tec was one of those companies to anticipate this monumental increase in demand and was able to take steps quickly to boost essential production.

Path-Tec is a market leading provider of comprehensive medical specimen management services, offering labs a complete outsourced solution. The company offers a suite of products and services including test kits, inventory management, specimen and supply logistics, courier management and client management technology. The company had the right mix of products and services required to help with essential Covid-19 testing. Understanding the urgency for Covid-19 testing and the supply chain challenges currently being faced, Path-Tec strategically partners with many different manufacturers to provide several options to their clients. The challenge was supporting an increasing number of labs and hospitals that have already begun Covid-19 testing.

Path-Tec quickly created a cross-functional Covid-19 task force consisting of operations, human resources, safety, and executive leadership. The task force would meet daily to discuss the latest information and determine any additional steps necessary to provide the essential kits. By taking all the necessary steps to protect their employees, Path-Tec was able to minimize any negative impact on staff, but they knew the avalanche of demand by customers was coming. The need for Covid-19 test kits was increasing dramatically, and it became a first priority to identify ways to streamline overall operations. Managers realized a key production pinch point would occur in the packaging department; this precipitated an initial search for packaging solutions on Google. There, after extensive research, Path-Tec discovered PAC Machinery. The next step was to identify which of the many PAC machines to choose from would serve their needs most accurately. Time to contact PAC.

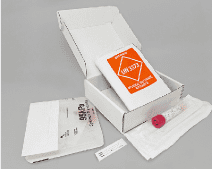

A PAC Machinery Regional Sales Manager was there to field the inquiry. After careful analysis of the packaging production line – and consultation with PAC Application Engineers, he envisioned a solution to meet the increased packaging demand for Covid-19 test kits. The solution was in the form of a RollbagTM R1285 automatic bagger and a large quantity of clear, pre-opened, 6”x10” poly bags on a roll. While the sales manager had dialed in the machine and bags, he needed to partner with a local packaging distributor to install the machines and train and support the staff at Path-Tec. He needed an organization with the technical bandwidth to get the job done right as there was no time to waste. His choice was a proven Atlanta, Georgia-based resource with whom PAC worked many times.

High performance in a small footprint

The sales manager explained to Kevin Boykin, the CEO and founder of Path-Tec that the Rollbag R1285 automatic bagger is the fastest tabletop bagging system on the market to feature an integrated next bag out thermal printer. Pac’s sales manager was confident stating that it would be an effective, production-boosting solution for Path-Tec. Equipped with a reliable thermal transfer printer, the R1285 automatic bagger would deliver the increased capacity required for packaging virus test kits in clear, lot and date-coded poly bags. The R1285 automatic bagger is designed to work with plain or custom printed pre-opened bags on a roll and could be used to seal bags up to 11″ wide. Because the R1285 bagger uses compressed air, Path-Tec would get the same performance from the R1285 as with a larger bagging systems, but in a much smaller package. These features result in a versatile, multi-shift solution. To make integration into the Path-Tec facility easier still, the R1285 bagger features a 7″ HMI touchscreen interface that is easy for people of all skill levels to learn and operate. As a result, no time would be wasted on lengthy training.

Kevin Boykin acted decisively and two Rollbag R1285 Auto- matic Baggers were ordered immediately. Four additional machine were purchased following the initial order.

Kevin Boykin acted decisively and two Rollbag R1285 Automatic Baggers were ordered immediately. Four additional machine were purchased following the initial order. The machines were configured to the customer’s specifications, carefully run through the PAC Machinery Quality Control process and prepared for shipping in record time. The first batch of the 1.5 million clear poly bags was on its way as well. In no time, decisive planning by Path-Tec and quick action by the distributor and PAC Machinery solved the packaging challenge and increased capacity of a most vital product. It was a success in challenging times and not a moment too soon.

Kevin Boykin acted decisively and two Rollbag R1285 Automatic Baggers were ordered immediately. Four additional machine were purchased following the initial order.

Watch the Rollbag R1285 in action

More about the R1285 Automatic Bagger here>>