Packaging Story

QuVa Pharma: When Quality Packaging Is More Than Just A Goal

QuVa Pharma: When Quality Packaging Is More Than Just A Goal

For Sugarland, Texas-based QuVa Pharma, quality is built into every process they follow. Quality is evident in every system and facility they operate, everything they make, whom they employ, and how they work. QuVa offers hospitals reliable access to a broad portfolio of sterile medicines required by physicians and needed by patients – for QuVa, quality is their north star.

As a 503B Compounding Pharmacy, QuVa follows equally stringent guidelines at every step of its product lifecycle – from design and validation to monitoring and continuous improvement. 503B compounding pharmacies provide patient-specific medications and test kits held to higher regulatory standards, and these facilities are required to maintain full compliance with the most current manufacturing practices. Performance testing helps ensure their operation is in a predictable state of control and can deliver the highest quality results at every step. From the operating room to the obstetric delivery unit to ICU, pharma-grade quality is omnipresent in everything they do. This level of no-compromise quality extends to its product packaging as well.

Keeping up with demand

The folks at QuVa realized they needed a new packaging approach to keep up with their growing business. They planned a visit to PACK EXPO Las Vegas – which was co-located with Healthcare Packaging EXPO. This expo is the premier packaging exhibition and is held in Las Vegas, NV, and Chicago. IL on alternating years. Included in the exhibitor list was San Rafael, California-based PAC Machinery. Pack Expo is where a knowledgeable PAC Regional Sales Manager had an opportunity to meet with the QuVa, Vice President, for the first time. The packaging application was discussed in general terms, as QuVa indicated they were in the discovery phase of their research and not ready to make an immediate decision. The PAC team was so confident they had identified the best solution, the sales manager was persistent in his approach to QuVa – and his persistence paid off. Within months of their initial contact QuVa’s VP and his packaging expert revisited PAC to discuss the project – this time in great detail.

The entire sales organization at PAC is trained to advocate for their customers, listen carefully, and consider all the unique goals their customers wished to accomplish. After considering several machines that could do the job, the team ultimately decided to recommend the Rollbag™ R785 Automatic Tabletop Poly Bagger; it checked off all the boxes – and then some.

Rollbag R785 Automatic Tabletop Bagger

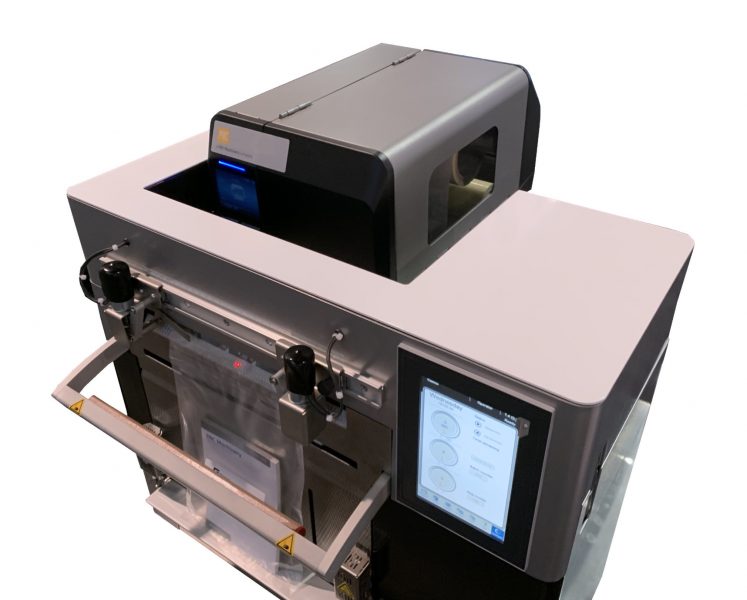

PAC’s regional sales manager explained that the Rollbag R785 is a unique, all-electric tabletop automatic poly bagger. This compact automatic bagger uses the same sophisticated electronics as PAC’s floor-standing industrial baggers and delivers a dependable, industrial quality, multi-shift packaging solution. It was ideal for what QuVa required. Engineered with an advanced control system, the versatile R785 operates at up to 40 bags per minute. This rapid speed means that the bagger is designed to run faster than it can be loaded by hand – ensuring that machine speed will never be the limiting factor in the packaging operation. Perhaps the most compelling feature was that the Rollbag R785 automatic bagger did not require compressed air, which means the QuVa facility would require no modification.

Add to the list of attractive features was the integrated label applicator which enabled QuVa to adopt a more fully-automated packaging process while maintaining their existing packaging. The applicator was perfect for applying their pre-printed labels and could both print and apply labels if they chose to do so. Add to this, the R785 is both easy to use and is exceptionally safe for the operator. Other benefits included flexibility: the bagger can be moved easily around the QuVa production environment and may be set up virtually anywhere with access to nothing more than an ordinary electrical outlet.

A prescription for success

In the final analysis, a couple of considerations became apparent. 1) QuVa required a unique set of features and benefits to streamline their packaging operation, and 2) PAC listened carefully, considered the requirements thoroughly, and recommend the correct choice among several machines from which to choose. The Rollbag R785 was not the most expensive choice – but it was the best fit. Everyone agreed; this automatic bagger was a quality machine that would serve dependably for years to come. For both PAC and QuVa, it was another successful prescription for a satisfied customer.

WATCH THE R785 IN ACTION

“Our quality is derived from rigorous cGMP processes. The QuVa product doesn’t come to you until it passes all established specifications”.

David Short Vice President of Quality QuVa Pharma Tweet