Packaging Story

Vacuum sealer helps define the word clean for the twenty-first century

Vacuum sealer helps define the word clean for the twenty-first century

For centuries, the word “clean” has been used to describe a general condition that is free of dirt, blemishes or contamination. But with the rapid evolution of emerging technologies, the war on particle contamination has been elevated to stratospheric levels.

The pursuit of an ultra clean manufacturing environment is not limited to the semiconductor industry. Now, the MEMS, microfluidics, medical device, advanced optics and laser industries, have pushed the pursuit of clean manufacturing to an entirely new level of importance. This said, nowhere is clean more important than in the wafer fab, where one near invisible trace of airborne particulate can contaminate a silicon wafer that has taken considerable time and numerous costly steps to process. Many modern cleanrooms (which are classified as ISO Class 1) now operate with airborne particulate levels limited to <0.1 microns per cubic meter. Clean processes and specialty materials extend to every activity that takes place in the cleanroom – from the use of high purity piping and fittings to non-contaminating process gases and liquids, to anti-static and non-outgassing packaging materials, pouches and bags.

When the subject turns to cleanroom packaging materials, few Silicon Valley suppliers know more than AeroPackaging. Founded in 1997, the business has expanded steadily, and as it grew, the demand for several new pieces of capital equipment grew as well. By 2016 an additional industrial vacuum sealer was on the list of the machines required to support the company’s growth. “We have relied on our Packaging Aids PVG Vacuum Sealer for years” states Ms. Carolle Van Someren, owner of AeroPackaging, “so we thought we would simply contact Packaging Aids for an additional unit”.

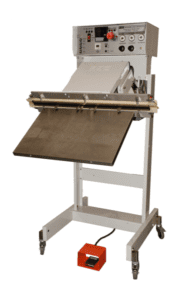

“One of the fundamental aspects of how we do business is taking the time to fully understand the challenges our customers are trying to solve,” offers Mr. Lawrence Warren, Western Regional Sales Manager for PAC Machinery. “While I believed a Packaging Aids PVG Vacuum Sealer would be adequate, I had a hunch we had a better solution”, continued Warren. Larry was correct. When he met with Van Someren, he introduced her team to the Packaging Aids Electro Pac Vacuum Sealer.

Designed specifically for applications in the electronics industry (where seal integrity and consistent vacuum level are critical), the Electro Pac delivers. With the SureTemp™ impulse temperature controller, every bag is sealed at the same temperature every time. The vacuum level sensor, which is standard on this model, maintains consistent vacuum levels on every sealing cycle as well. The Electro Pac has a 0.3125″ wide seal element in each jaw to effectively seal foil, laminates, and the other thick materials that AeroPackaging use regularly. The vacuum sealer that Larry recommended was configured with ported exhaust, which combines all exhaust air into one port that can be vented outside the cleanroom facility. For added versatility, the Electro Pac sealer has the ability to flush the bag with nitrogen or other inert gas to drive out destructive oxygen prior to sealing. “We knew what we wanted in a vacuum sealer, but Larry helped us choose what we actually needed. He was more than a salesman – he was a consultant who partnered with us to find the best solution for our unique business”, adds Van Someren.) The order for the Electro Pac was filled and the machine was pressed into action immediately.

AeroPackaging has adopted the slogan “The Exclusive Clean Film Manufacturer” for a very good reason. They are the only manufacturing facility designed for the exclusive purpose of producing cleanroom packaging film. This single-purpose vision means they do not compromise in any aspect of their business – and this commitment to quality extends to the equipment they choose as well.

“Our sales rep was more than a salesman – he was a consultant who partnered with us to find the best solution for our unique business.”

Carolle Van Someren CEO & Founder AeroPackaging Tweet