PAC Machinery Enters Its First Flow Wrapper To Package With Paper In addition to Plastic for MHI’s Best New Innovative Sustainable Product Award at Leading Show for Supply Chain and Manufacturing

FOR IMMEDIATE RELEASE

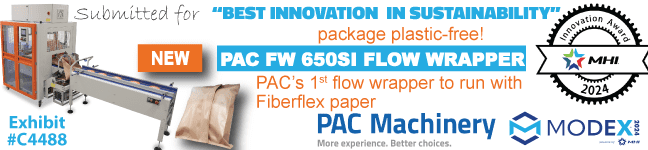

PAC Machinery (PAC), Leaders in packaging with one of the most diverse ranges of machinery, has entered its PAC FW650SI Flow Wrapper in the MHI Innovation Award competition for “Best New Innovation in Sustainability,” a new category added for the 2024 competition. PAC Machinery’s FW 650SI Flow Wrapper just debuted in October 2023, as PAC’s first flow wrapper to package with both poly and PAC’s new, innovative, Fiberflex® paper packaging material. FW 650SI Flow Wrapper provides industries that flow wrap, with a complete plastic-free packaging system. MHI is the largest material handling, logistics and supply chain association and producer of the MODEX show among several others.

FW 650SI was designed to work specifically with PAC’s new Fiberflex high-performance, eco-friendly paper for flow wrapping, that can be conveniently discarded for recycling curbside. Fiberflex can also be made with recycled content options. It helps companies achieve sustainable goals, package safer and reduces plastic in the environment.

Industries served with the FW 650SI Flow Wrapper include: food, electronics, bakery, candy, industrial manufactured parts, medical devices and other industries that wrap products at high speeds.

“PAC Machinery is leading the way in sustainable packaging solutions and we are thrilled to have this opportunity through our industry partner, MHI, to showcase both new innovative technology in packaging equipment and in the materials that we offer, said Greg Berguig, Vice President of PAC Machinery. “This packaging solution provides two eco-friendly solutions with innovations in both the machinery and the sustainable paper packaging, providing a way for companies to reduce reliability on plastic and improve their sustainable impact,” Berguig said.

The inaugural MHI Innovation Awards were first handed out in 2013.

“As the industry evolves and advances, MHI is committed to highlighting sustainable practices in the supply chain industry, and we are proud to announce a new category to our annual Innovation Award program, with our inaugural Best Innovation in Sustainability category,” said Greg Baer, Vice President, Sales MHI. “This award category aims to recognize and celebrate MODEX 2024 exhibitors that are delivering solutions to help their customers integrate sustainable practices within their supply chain operations and push for positive change within the material handling and supply chain industry,” Baer said.

Winners will be announced at the 2024 MODEX show in Atlanta, GA at the World Congress Center during the show held March 11-14, 2024. The MHI Innovation award highlights the latest innovations for manufacturing and supply chain. The submitted products are promoted on the MODEX website.

According to MHI, 48% of attendees that visited the MHI Innovation Awards page, visit the finalist’s exhibit. Show attendees can visit PAC Machinery at exhibit #C4488 where top-selling automatic bagging solutions for fulfillment will be shown with other sustainable material options.

###

FOR SALES: sales@pacmachinery.com 1.800.985.9570