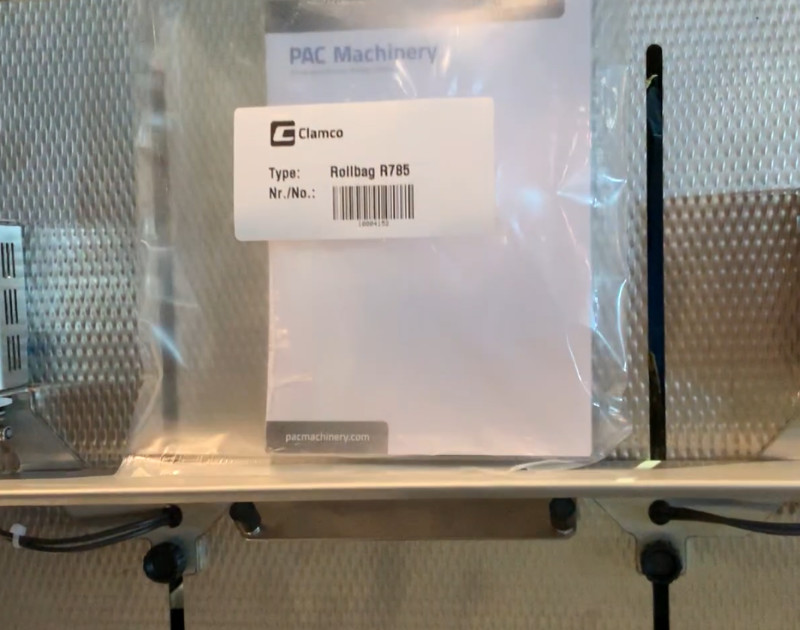

All-Electric Automatic Bagger

The Rollbag R785 is a unique, all-electric tabletop automatic poly bagger. This compact automatic bagger uses the same electronics as our larger floor standing baggers, delivering a dependable, industrial quality, multi-shift packaging solution. Using an advanced control system, the R785 is able to operate at a rate of up to 40 bags/min, ensuring machine speed is not the limiting factor in your packaging operation. The Rollbag R785 automatic bagger does not require compressed air, which means the facility needs no modification. This bagger can easily be moved around the production environment and may be set up virtually anywhere with an ordinary electrical outlet. Positioning this poly bagger is made even easier by its small footprint (26” wide x 18” deep), and lightweight (just over 100 lbs) making it easy to move. The R785 automatic bagger can be cycled by pressing a footswitch, tapping the seal bar, touching the optional easy touch sensor, or automatically.

Flexible Poly Bagging

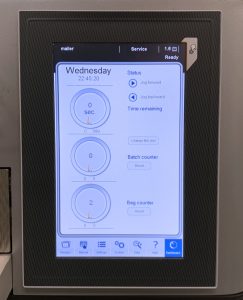

Flexibility is critical for packaging products in poly bags. Therefore, the R785 automatic bagger is engineered to accommodate poly bags on a roll up to 12” wide and 20” long. The high-power sealing magnet creates hermetic seals in poly bags up to 4 mil. in thickness. The R785 automatic poly bagger features a user-friendly touchscreen interface with the capacity to store up to 50 jobs. Job storage makes product set-up a breeze. Furthermore, the rolls of pre-opened bags are loaded from the front, so access to the back of the machine is not required during regular operation.

A Range of Features to Optimize your Bagging Process

R785 automatic bagger has a host of standard features—most of which are not available on other all-electric poly baggers. One example is the seal flattener feature where fingers automatically stretch the poly bag tight prior to sealing. This step can minimize wrinkles in the seal. The articulating bag support allows heavy products to be handled more easily, by supporting the bottom of the poly bag during packaging. At the end of the cycle, this support automatically tilts down, allowing the product to drop into a bin or conveyor. The load shelf can be adjusted to various angles, ensuring optimal set-up for bulky products.

Automatically Print Directly on your Bags

Truly a next-generation automatic poly bagger, the R785 is the first all-electric bagger that offers an optional integrated label printer applicator as well as thermal transfer printer. The thermal transfer printer prints directly on the bag while the off-the-shelf industrial labeling solution prints and applies a label on the first bag to be fed out. This is ideal for applications like poly mailers that require a shipping label or other data that changes with each bag. Because you can print and apply a scannable barcode label directly on the bag, bags that are clear on both sides can be used. As the label printer applicator works with direct thermal labels, as well as thermal transfer, there is no need for any printer ribbon.

Custom pre-printed labels with high color graphics can also be used for a customer experience that greatly enhances your brand. The R785 automatic bagger is particularly effective for short batch runs and is the ideal transition for customers currently packaging their product by hand in reclosable zipper bags with a label that is manually applied. The Rollbag R785 is able to print up to 4″ in width, either directly on the bag or with labels.

Engineered with Uptime and Safety in Mind

Safety is a critical consideration in every production environment. With a CE-compliant design, you can be assured that R785 automatic poly bagger meets the latest safety standard for packaging machinery. Owed to its unique design, the seal bar on the R785 bagger closes without force, virtually eliminating any chance of injury. The robust R785 is built to last, however, after years of use components can fail. Therefore, the R785 has been designed with as many off-the-shelf components as possible. Furthermore, side covers are properly secured with only a handful of screws so they can be removed quickly and easily. The result is that all internal components of the machine can be accessed in minutes. In addition, the seal bar can easily be changed out by unfastening readily accessible bolts. For added peace of mind, we will extend the warranty of our R785 (from the standard one year) up to three years, with the exclusive use of Rollbag® brand pre-opened bags on a roll.

Versatile Design for a Range of Industries

The Rollbag R785 automatic poly bagger works well in a wide variety of poly bagging applications. These include mail order fulfillment, aerospace, injection molding, kitting, pharmaceutical, medical device, automotive, food, and more. Contact PAC Machinery today to learn how the R785 Automatic Bagger can help you improve your poly bagging process. Financing Options from $210/month.